We recognize that there are thousands of applications that are new, unique, or too complicated, such that no generic product could meet all the needs. For this reason, Axiomatic offers rapid development of new control solutions and/or application-specific software for existing Axiomatic controls.

Collaboration

Axiomatic’s design team works closely with our customers to understand application requirements and to look for innovative and effective solutions. Our team encompasses electrical, software, mechanical, performance and environmental validation, and quality engineering expertise. Our product development schedule includes key milestones with regular customer feedback. From prototype to production, Axiomatic strives to provide an effective and rapid design process. Since problems are often complex and multi-sided, we engage in a collaborative process to bring different points of view into focus.

Innovation in Controls Design

Axiomatic has over the years developed a wide range of technology building blocks leading to control, power conversion and motor drive solutions. Such a strong foundation often leads to a high-velocity solution – moving quickly in the right direction. A commitment to continuous R&D for circuit and product development leads to innovation, energy efficiency and cost-effective technology. We utilize the latest industry standards and tools for design.

A data analysis approach in our engineering design is our goal. Engineering design capabilities include electronics schematic design; multi-layer circuit board layout design; 3D mechanical design; thermal modeling; software design and modeling; product performance validation; and MTBF analysis. New product enclosures can be prototyped using our 3D printer for early feedback during the prototype phase.

New Product Introduction Process

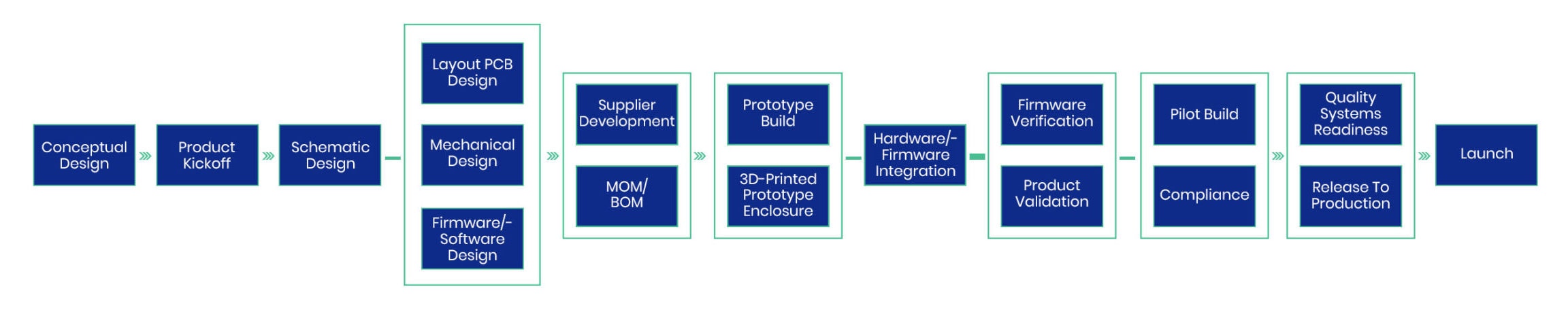

Development schedules are established with key milestones and dates in consultation with each customer. Rapid prototype development is a key service.

Our product development milestones include project reviews at different stages:

- Schematic Design;

- PCBLayout and Mechanical Design;

- Prototype Build;

- Pilot / Pre-production Build;

- and Release to Production.

Engineering tools utilized in the development process include:

- Design calculations and simulation (LTspice IV, PTC Mathcad);

- Schematic capture (Altium Designer);

- Mechanical Design (Autodesk Inventor® 3D CAD);

- Thermal Analysis (Thermal Solutions Inc. Sauna™);

- MTBF (Isograph Reliability Workbench);

- Software Development (MathWorks® Simulink®, Keil C);

- Enclosure Prototyping(in-house 3D printer);

- DFMEA (AIAG);

- and others.

All controls are evaluated for production manufacturability during the design process.

Product enhancements can provide value throughout the product life cycle, helping to achieve a long “in service” period.

Product Quality Planning and Part Approval

Axiomatic responds to customer-based quality planning and part approval processes such as APQP, ISIR, PPAP, and Measurement Studies (MS). Axiomatic prototype and production-ready controls are manufactured in-house at our ISO 9001 facility in Mississauga, Ontario, Canada. Product hardware, firmware and mechanical design elements are managed under ECN change control and this process is linked to our ERP system.

Product Compliance

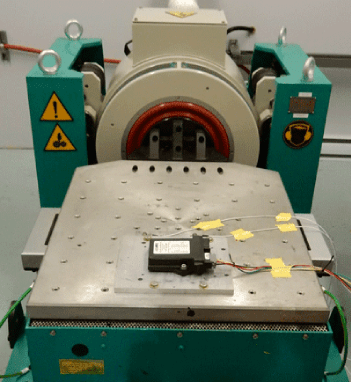

We undertake electrical testing (engine cranking, load dump, etc.), EMC and environmental performance testing to suit the application. Third-party certifications may be included as part of a development program (UL, CSA, ATEX, DNV Type Approvals, etc.)

Declarations of Conformity to EU Directives, Type Approvals, and other product performance certifications are available on the Part Number Index. We utilize the SiliconExpert P5 Platform for product compliance information on RoHS, REACH, Proposition 65 and other materials regulatory requirements.

Regulatory changes in the electronics manufacturing industry, application end use industries as well as from our customers’ regulatory jurisdictions worldwide are part of our product change control system.