Axiomatic Technologies Corporation designs and manufactures diverse automation controllers in Canada. Our signal conversion controls are used in control panels and automation systems for engine, off-highway, mining, municipal, commercial, and industrial installations where precision is required. With a strong installed base of products and our years of design expertise, we deliver quality signal converters and signal conditioners.

Automation systems use a variety of fieldbuses for networking devices. Signal converters and signal conditioners process, isolate signals and convert them to another type of signal. Signal converters with SAE J1939 or CANopen® are available. We also support RS-232. Many Axiomatic signal conditioners interface with 4-20mA from a PLC or a PWM signal from an Engine ECM. Voltage signals and current signals are typical analog inputs for our signal processing product line. Digital signals including frequency are user configurable. DIN Rail mounting is a common form factor. IP67 rated signal conversion modules are suited for harsh applications.

Some benefits of signal converter solutions include:

- Conditions the signal from one device to another for further processing

- Filter, compress, and amplify signals

- Normalizing signals

- Remove distortion caused by external interferences

- Signal conversion, measurement, and monitoring

- Accuracy and resolution

- Isolation between power, inputs, and outputs

- Networking multiple devices

- Extend machine networks by adding I/O to the CAN bus

- Interference-free signal transmission

- DIN Rail form factor for control panels

- Durability to withstand harsh conditions

Signal Converters and Signal Conditioners from Axiomatic

Axiomatic automation solutions include industrial signal converters and conditioners for standard DIN Rail applications. Our rugged line of signal conditioning and conversion controls is suitable for harsh environments.

Signal Converters

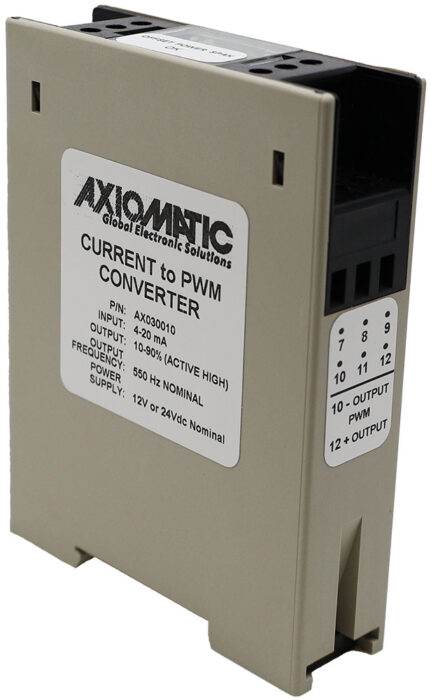

We offer multiple types of converters. These signal processing devices support current, voltage, PWM, frequency, and digital inputs and/or outputs. We offer analog signal converters along with digital solutions. We also have IP67 sealed and DIN Rail form factors. Our converters can be tuned or are fully user configurable to suit diverse applications. We also offer design services for custom solutions.

Our signal converter products include:

Signal Converter Bridges Vs Gateways

Signal converter bridges and gateways serve fundamentally different roles in industrial automation networks, with their distinction rooted in the OSI network layers where they operate and the complexity of their protocol handling capabilities. A bridge operates at the data link layer (Layer 2) and primarily connects two or more network segments that use the same protocol, such as linking multiple Ethernet LANs together. Bridges filter traffic by examining MAC addresses and only forward packets to segments that need them, reducing network congestion while maintaining protocol transparency—they simply pass all protocols along without distinction or modification. In industrial applications, bridges help reduce network traffic by only forwarding packets to the segments that need them, examining destination addresses and forwarding only to appropriate segments. Modern multi-port bridges are often called Layer 2 switches because they perform similar functions but with enhanced capabilities.

Gateways, conversely, are far more sophisticated devices that operate at multiple network layers and excel at protocol conversion between disparate systems. Unlike bridges which simply communicate information, gateways repackage and manipulate application layer protocols, translating data between networks using entirely different communication standards. In industrial automation, gateways enable communication between diverse protocols like Modbus RTU to EtherNet/IP, DF1 to Modbus TCP, or CANopen to Profibus, performing critical protocol conversion, data translation, and filtering functions. Modern industrial gateways have evolved beyond simple protocol conversion to include IIoT capabilities, featuring standard microprocessors, operating systems, and APIs that support REST, MQTT, and OPC UA for cloud integration and edge computing functions. While bridges connect similar networks efficiently, gateways solve the complex challenge of integrating legacy equipment with modern systems across different protocol families, making them essential for Industry 4.0 transformations.

Signal Converter Protocol Matching

Protocol matching in signal conversion represents the critical process of ensuring electrical and communication compatibility between disparate industrial devices, extending beyond simple protocol translation to encompass signal conditioning, impedance matching, and data format standardization. Modern protocol converters support up to 300 industrial communications drivers and can process up to 20 unique protocols simultaneously, serving as universal translators that convert between legacy protocols like Modbus RS-232 and modern standards like OPC UA, MQTT, and EtherNet/IP. Signal converters perform multiple critical functions including converting analog signals to digital formats for PLC compatibility, adjusting voltage and current levels, providing galvanic isolation, and normalizing signals from thermocouples, RTDs, and load cells into standardized ranges like 4-20mA or 0-10V. In industrial automation systems, protocol matching involves converting low-level temperature and pressure signals into robust current-loop signals that can be transmitted over thousands of feet while maintaining precision, with differential inputs providing high common-mode rejection and A/D converters enabling digital processing by PLCs and control systems. Unlike bridges which operate transparently at the data link layer, or gateways which focus on application-layer protocol conversion, protocol matching converters address the fundamental electrical interface challenges—ensuring proper impedance matching, signal amplification, noise filtering, and electrical isolation—that make communication between different generations and types of industrial equipment possible in mixed-protocol environments.