AC to DC Converters — AC-DC Converters

Table of Contents For AC DC converters

- How AC/DC Power Supply Works

- Requirements of an AC to DC Converter

- Benefits of an AC-DC Converter

- AC-DC Converter Topologies & Trade-offs

- Design Calculations & Example Sizing for a AC to DC converter

- Guidelines for Selecting a AC-DC Converter

- Steps to Choose an AC/DC Converter

- Standards, Certifications & Compliance

- FAQ / Troubleshooting of Your AC-DC Converter

- Conclusion

How AC DC Power Supply Works

AC/DC converters (often called rectifiers) turn alternating-current (AC) into direct-current (DC). The basic flow for an AC-DC converter is:- Rectification – Diodes convert the sinusoidal AC waveform into a pulsating DC voltage.

- Filtering – Capacitors (and sometimes inductors) smooth the pulsating voltage, removing ripple.

- Regulation (optional) – A regulator stage holds the output voltage steady despite load variations.

- Transform mains AC into a stable DC.

- Eliminate any residual AC that could damage downstream circuitry.

- Keep the output voltage within tight tolerances.

Requirements of AC/DC Converter

When choosing an AC to DC converter power supply for industrial automation, IoT, or smart-home devices, keep these core requirements in mind:- Compact Size – Modern devices favor lightweight, space-saving designs.

- High Efficiency – Higher efficiency means less wasted heat and lower operating costs.

- Low Standby Power – Idle consumption of a few microwatts dramatically extends battery life.

Benefits of an AC/DC Converter

- Energy Efficiency – One converter replaces multiple stages, cutting conversion losses.

- Space-Saving – Compact modules free up board and enclosure area.

- Cost-Saving – Lower energy consumption and fewer components reduce total cost of ownership.

Topologies and Trade-offs

| AC-DC Converter Topology | Typical Use-Case For This AC to DC Converter | Advantages of This AC-DC converter | Disadvantages of This AC-DC converter |

|---|---|---|---|

| Fly-back | Low-power adapters, isolated supplies (<30 W) | Simple, inexpensive, inherent isolation | Higher ripple, limited power |

| Forward | Medium-power isolated supplies (10-100 W) | Better efficiency, lower ripple | Needs output transformer, slightly larger |

| Buck-Boost (SEPIC, Cuk) | Battery-powered devices | Wide output range, non-inverting output | Lower efficiency, more components |

| Resonant (LLC) | High-efficiency (>95%) industrial supplies | Very low EMI, excellent regulation | Complex design, more parts |

| SiC / GaN based | High-frequency, ultra-compact | Extremely high efficiency, tiny parts | Higher cost, thermal management |

AC-DC Converter Design Calculations and Example Sizing

- Power Budget Iout = Pload / (Vout × η) Example: 12 V, 5 W sensor → Iout = 0.46 A → Select ≥ 0.5 A converter.

- Thermal Design Ploss = VinIin - VoutIout Example: 120 VAC input, 12 V × 0.5 A output, 90% efficiency → Ploss ≈ 2.4 W. ΔT = Ploss × RθJA = 72 °C. Junction ~97 °C at 25 °C ambient.

- Component Selection Flow Define input → Pick topology → Select controller IC → Add protection → Validate in simulation.

Guidelines for Selecting a Converter

- Efficiency ≥ 90% (≥ 95% for battery devices)

- Isolation Voltage ≥ 1.5 kV for safety-critical designs

- Package: DIP/SMD for PCB, TO-220 for higher-power

- Standby Power ≤ 10 µW for IoT sensors

- Environmental Rating: temperature & IP protection

Standards, Certifications, and Compliance

| Domain | Relevant Standard(s) | Why It Matters |

|---|---|---|

| Safety | IEC 62368-1, UL 60950-1 | Protects users from hazards |

| EMC | IEC 61000-4-2, IEC 61000-4-3 | Limits interference |

| Efficiency | EU Ecodesign, ENERGY STAR | Meets regulatory limits |

| Materials | RoHS, REACH | Restricts hazardous substances |

| Automotive | ISO 26262 | Ensures vehicle safety |

- [ ] UL/CE marked?

- [ ] Meets IEC 62368-1?

- [ ] EMI/EMC tested?

- [ ] RoHS compliant?

- [ ] ISO 26262 for automotive?

FAQ – Troubleshooting For AC-DC Converters

| Problem | Likely Cause | Suggested Remedy |

|---|---|---|

| Output voltage drifts | Insufficient capacitance or loop instability | Increase Cout, adjust compensation |

| Converter runs hot | Poor thermal path, high quiescent current | Add heatsink, use efficient topology |

| Excessive ripple | Inadequate filtering | Add LC filter, ferrite beads |

| Fails at startup | Inrush exceeds ratings | Add NTC or soft-start circuit |

| Isolation breakdown | Poor PCB spacing, transformer fault | Redesign spacing, test isolation |

Conclusion

Modern AC/DC converters power everything from smart-home hubs to EV fast chargers. By understanding topology choices, performing power and thermal calculations, following standards, and anticipating troubleshooting issues, designers can build converters that are efficient, reliable, and compliant.Browse by Product Category

Tell Us Your RequirementsVAC to 12 or 24 VDC, AC/DC Power Supplies

The AC/DC Converters accepts a wide range of inputs (95-260 VAC), and have either a 24 VDC, 15 A output, or a 12 VDC, 30 A output. They are designed for mounting in a vehicle or in a stationary engine. Axiomatic's AC/DC units manage heat dissipation, so no fan cooling is required, and have a high efficiency rating.

4 Parts

View AllCan’t find what you’re looking for?

We offer fresh design ideas and rapid prototyping that caters to the needs of OEM’s from different industries relying on battery-powered control systems. Contact us for customization or new product design.

Tell Us Your RequirementsFeatured AC to DC Converters — AC-DC Converters

Center Bonded Mounts

Center Bonded Mounts STA Series

All Product Categories

1

Automation

2

Power Management

3

Connectivity Solutions

4

Machine Control

5

Accessories

I/O Controls & Signal Converters

View All

Engine Temperature Monitoring Solutions

View All

Hydraulic Valve Drivers & Controllers

View All

Signal Input Controllers with CAN

View All

Signal Output Controllers with CAN

View All

Signal Inputs, Signal Outputs, CAN Converters

View All

I/O Modules with Relay Outputs and CAN

View All

Signal Input Controllers with Modbus TCP/IP

View All

LED Outputs CAN Controllers

View All

LVDT and LVDT/RVDT Simulators, DIN Rail Mount

View All

Multi-Channel Strain Gauge CAN Controllers

View All

Wake-On-Charge Module, CAN

View All

Multiple Cell Battery Voltage Monitors

View All

PWM to Voltage or Current Signal Converters, DIN Rail Mount

View All

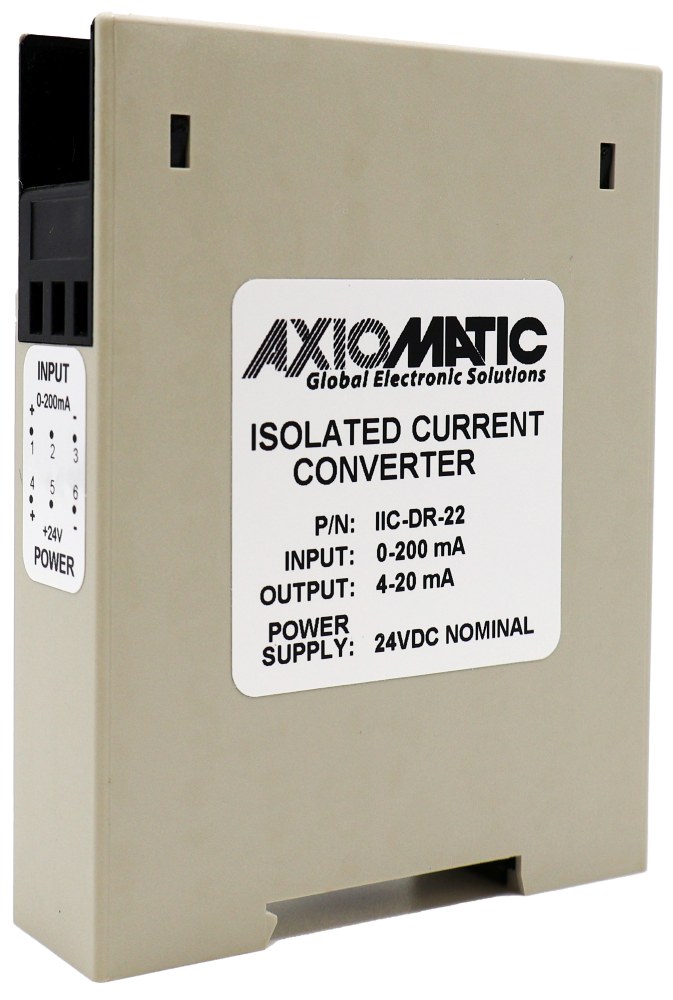

4-20 mA Current to Current Converters, DIN Rail Mount

View All

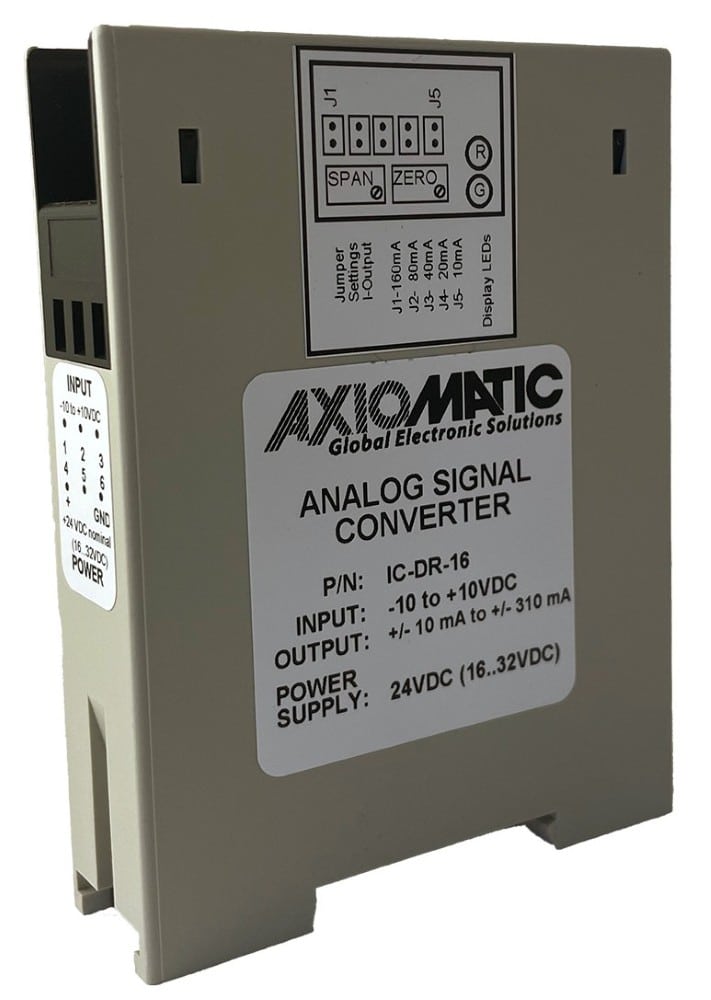

Voltage or Current to Bipolar Current Converters, DIN Rail Mount

View All

1 Universal Signal Input CAN Controllers

View All

Universal Signal Input CAN Controllers, Compact

View All

Magnetic Pickup Input to CAN Converters

View All

Magneto-Resistive Speed Sensor Input Controller, CAN

View All

RS-232 to CAN Converters with 2 Digital Inputs

View All

4 Universal Signal Inputs Controllers

View All

4 Digital Inputs Controller with CAN and Ethernet

View All

6 Digital Inputs Controllers

View All

10 Universal Signal Input CAN Controllers

View All

12 Channel Strain Gauge - CAN Controller

View All

18 Digital Inputs CAN Controllers

View All

CAN to Sine or Square Wave and PWM Output Controller

View All

1 Resistive Output CAN Controller

View All

1 Analog Signal Output CAN Controllers

View All

CAN to PWM Signal Controller

View All

CAN to 1 Signal Output Controllers

View All

CAN to 2 Analog/Digital Isolated Signals and 1 Relay Output Converters

View All

CAN to 2 Analog/Digital Signals and 1 Relay Output Converters (Compact)

View All

4 Signal Outputs CAN Controllers

View All

12 Signal Output Controllers

View All

Voltage or Current to PWM Signal Converters

View All

PWM to Current Signal Converters, DIN Rail Mount

View All

PWM to Voltage Signal Converters, DIN Rail Mount

View All

0-200 mA to 4-20 mA Isolated Current Converters

View All

1 Input, 1 Output, Isolated Signal Converter

View All

Bipolar Input, Relay and Analog Signal Output Controller, NFC, DIN Rail Mount

View All

1 Digital Input, 2 Relay Outputs Controller, Isolated CAN, DIN Rail Mount

View All

Universal Signal Converter with Three-way Isolation, DIN Rail Mount

View All

Intelligent Load Control Switch

View All

Economy Dual Channel Universal Signal Converters

View All

Isolated Dual Universal Signal CAN Converters

View All

Isolated, Dual Channel, Universal Signal CAN Converter, NFC, DIN Rail Mount

View All

4 AC Voltage or Current Inputs, 4 Analog Outputs CAN Controllers, DIN Rail Mount

View All

2 Bipolar Analog/Digital and 8 Universal Signal Inputs Controller, Ethernet Port, DIN Rail Mount

View All

2 Bipolar Analog/Digital and 8 Universal Signal Inputs Controller, DIN Rail Mount

View All

3 Encoder, 7 Signal Inputs CAN Controllers, Isolated

View All

11 Input to 9 Output CAN Controllers

View All

12 Inputs, 8 Analog and 1 Relay Outputs CAN I/O Module

View All

16 Inputs, 15 Outputs Interface Modules

View All

21 Inputs, 6 Outputs, Isolated Dual CAN Controllers

View All

Resistance Temperature Detector (RTD) Modules

View All

Thermocouple (TC) Modules

View All

DIN 43650A Valve Controllers & Amplifiers

View All

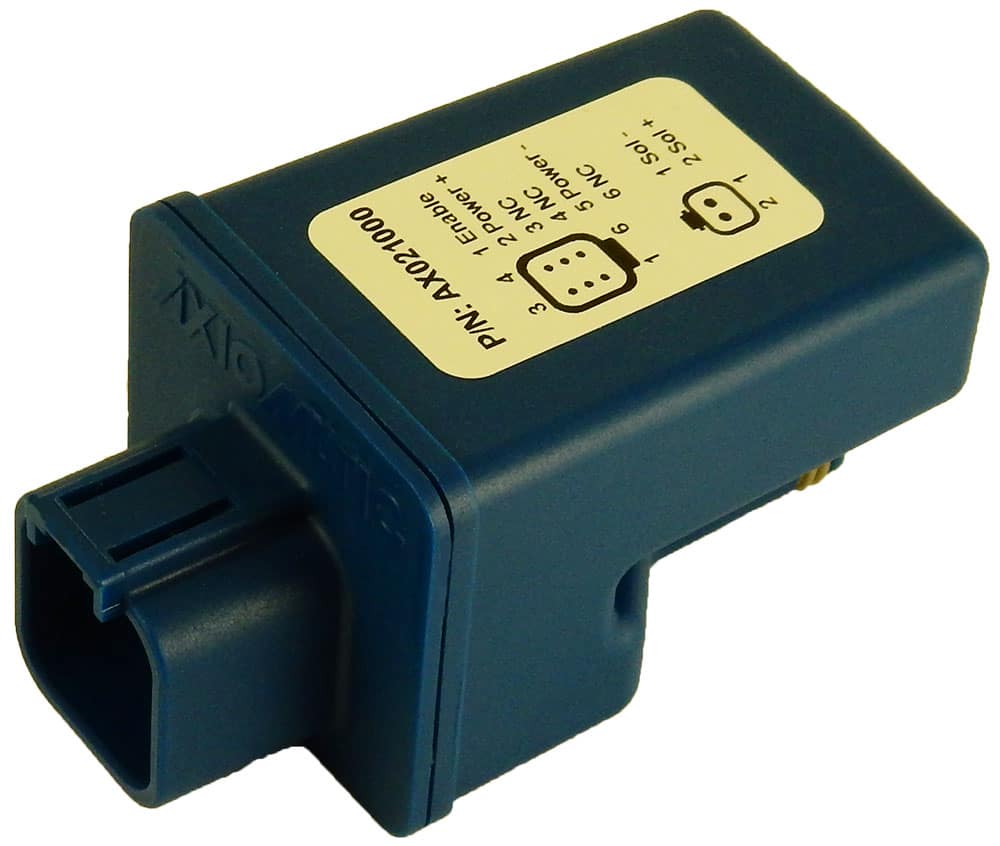

Plug-In Valve Controllers

View All

CAN to Outputs Valve Controllers

View All

Proportional Output Controllers with Signal Inputs

View All

Encoder Input, Dual Output Valve Controllers

View All

H-Bridge Controllers

View All

Digital On/Off Valve Controllers

View All

Dual Servo Valve Controllers

View All

Controllers with Near Field Communication (NFC)

View All

Remote Mount Solenoid Drivers, PCB or Metal Box

View All

Remote Solenoid Drivers, 1 Analog Input, 1 Output, DIN Rail Mount

View All

DSDA-SMB-x Dual Solenoid Multifunction Valve Drivers

View All

Pulsar Valve Controller, SAE J1939, 250kbps

View All

12V or 24V Hot Shot Solenoid Protection Controllers

View All

Economy Analog Valve Controllers, DIN Rail Mount

View All

Single Output Plug-In Valve Controller

View All

CAN to 1 Output Valve Controllers

View All

CAN to 1 Output Valve Controller, DIN 43650A

View All

CAN to 2 Outputs Valve Controllers

View All

Dual Output Plug-In Valve Controllers

View All

CAN to 4 Outputs Valve Controllers

View All

CAN to 6 Output Valve Controllers

View All

10 Outputs Valve Controllers

View All

CAN to 10 Outputs Valve Controllers

View All

Universal Input, Single Output Valve Controllers, Near Field Communications (NFC)

View All

1 Universal Input, 1 Output Valve Controllers with LED

View All

Single Input, Dual Outputs Valve Controllers

View All

1 Digital Input, 2 Digital Outputs Valve Controllers with CAN

View All

1 Universal Input, 2 Outputs, Valve Controller, Plug-In

View All

2 Inputs, 2 Outputs Valve Controllers

View All

Dual Input, Dual Output Valve Controllers, DIN Rail

View All

4 Inputs, 2 Outputs, +/- 400 mA Valve Controllers

View All

4 Inputs, 2 Outputs, 3A Valve Controllers

View All

4 Inputs, 8 Proportional Outputs Valve Controllers

View All

6 Inputs, 5 Outputs Valve Controllers

View All

7 Input, 5 Output Valve Controller, SAE J1939

View All

7 Digital Inputs, 6 Digital & 4 LED Outputs Controllers

View All

8 Input, 5 Output Valve Controllers

View All

12 Inputs, 12 Outputs Valve Controllers

View All

CAPVE-H-5V-XA-5C-2M Economy Connector Amplifiers for Proportional Valves

View All

CAPV-H-5V-x Connector Amplifier For Proportional Valves

View All

CAPV-H-10V-X Connector Amplifiers for Proportional Valves

View All

CAPV-H-4-20MA-X Connector Amplifiers for Proportional Valves

View All

SSD-H-t-02-x-yM Soft Shift Controllers

View All

3A Solenoid Drivers

View All

Remote Mount Solenoid Driver (0-5 Vdc/0-20 mA/10 K Potentiometer Input)

View All

Remote Mount Solenoid Driver (0-10 Vdc Input DC)

View All

Remote Mount Solenoid Driver (4-20 mA Input)

View All

Bumpers

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

Battery Chargers

View All

DC to DC Converters — DC-DC Converters

View All

Motor Drives and Controllers

View All

Surge Protectors

View All

AC to DC Converters — AC-DC Converters

View All

24VDC, 15A Battery Charger with CAN bus

View All

12VDC, 25A Battery Charger with CAN Bus

View All

24VDC/14VDC, 2A Battery Charger/Converter for SLA and AGM Batteries with CAN Bus

View All

24VDC, 1.2A Battery Charger for Lithium-ion Batteries with CAN Bus

View All

48VDC to 12 or 24VDC, 2A Battery Chargers/Converter with CAN Bus

View All

12VDC Input Power Converters

View All

12VDC to 12VDC Power Converters

View All

12 or 24VDC to 24VDC Converters

View All

12 or 24VDC to 48VDC Converters

View All

24VDC to 12VDC, Isolated Converters

View All

24VDC to 24VDC, Isolated DC/DC Converters

View All

Power Supplies with Back-up Time

View All

24VDC to 72VDC, Isolated Converters

View All

12 or 24VDC to 120-140VDC Power Converters, DIN Rail Mount

View All

48VDC Input Power Converters

View All

48VDC to 24VDC Power Converters

View All

72, 96, or 110VDC to 12VDC, Isolated Power Converters

View All

72, 96, or 110VDC to 24VDC Isolated Power Converters

View All

72VDC to 36VDC Power Converters

View All

DC to DC Converters with CAN

View All

12 or 24V to 1A DC/DC Converters

View All

12VDC to 25VDC Converters

View All

15-60VDC to 24VDC Converters

View All

15-60VDC/24VDC, 240W Isolated Converter

View All

12VDC/12VDC, 18W Isolated Power Converter

View All

12VDC/12VDC, 180W Isolated Converters

View All

9-36VDC/12VDC, 18W Isolated Power Converter

View All

12VDC/24VDC, 60W Isolated Power Converters

View All

12VDC/24VDC, 170W Isolated Converters

View All

12VDC/24VDC, 190W Isolated DC/DC Converters

View All

12VDC/48VDC, 60W Isolated Power Converters

View All

24VDC to 12VDC, 5A Isolated Converters

View All

24VDC to 14VDC Isolated Converters

View All

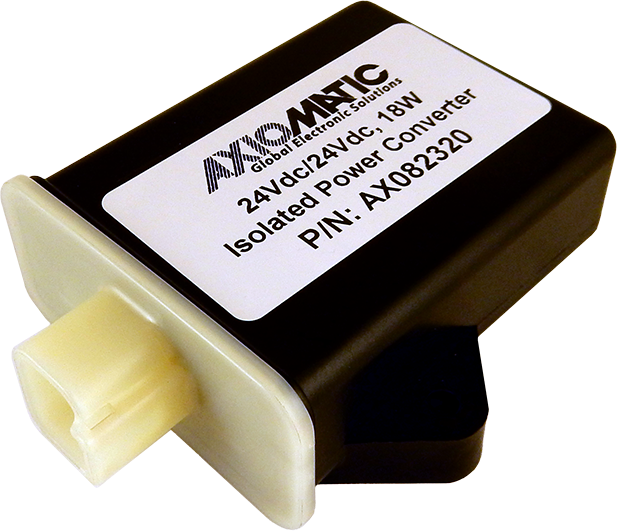

24VDC to 24VDC, 18W Converter

View All

24VDC/24VDC, 3A Isolated DC/DC Converters

View All

24VDC to 24VDC, 120-135W Isolated Converters

View All

24VDC to 24VDC, 10A Isolated Converters

View All

24VDC/24VDC, 500W Isolated Converter

View All

24VDC/24VDC, 720W, Non-Isolated DC/DC Converters

View All

24VDC to 48VDC, 60W Isolated Converters

View All

48VDC to 12VDC Power Converters

View All

48VDC to 13.8VDC Converters

View All

48VDC/24VDC, 720W Non-Isolated Step-Down Converter

View All

48VDC/24VDC, 13A Isolated DC/DC Converters

View All

48VDC to 26VDC Power Converters

View All

Stepper Motor Controllers

View All

Brushed DC Motor Controllers

View All

Brushless DC (BLDC) Motor Controllers

View All

Universal (DC or BLDC) Motor Controllers

View All

Unidirectional DC Motor Drives

View All

AC Transient Surge Protectors

View All

DC Transient Surge Protectors

View All

VAC to 12 or 24 VDC, AC/DC Power Supplies

View All

Bumpers

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

CAN Isolators/Routers

View All

CAN-Repeaters

View All

Automotive Ethernet Converters

View All

Automotive Ethernet Switches

View All

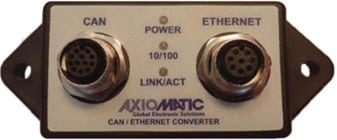

Ethernet/CAN Converters

View All

Ethernet Switches

View All

Ethernet Switches with PoE

View All

Modbus TCP/IP Converters

View All

Modbus RTU Converters

View All

Ethernet TCP/IP Gateways

View All

Isolated Protocol Converters with CAN & Modbus RTU or J1587

View All

LIN/CAN Protocol Converters

View All

CAN to Bluetooth® Modules

View All

RS-232 to CAN Modules

View All

CAN/Wi-Fi Modules

View All

Protocol Converter, Ethernet / RS-422 / RS-485 / RS-232 / CAN (SAE J1939)

View All

1 Universal Input Signal, 2x CAN, RTC Modules

View All

CAN ID NFC Controller

View All

CAN to USB Converters

View All

Data Loggers

View All

Fiber Optic to CAN Modules

View All

Modbus RTU to Modbus TCP/IP Routers with CAN

View All

Automotive Ethernet to CAN Converters

View All

Automotive Ethernet to Ethernet Converters

View All

Protocol Converters, SAE J1939, SAE J2497

View All

Bumpers

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

Rotary Laser Receivers

View All

Triaxial Gyroscope Inclinometers, M12 Connectors

View All

Triaxial Inclinometers, DT13-4P Connector

View All

Triaxial Inclinometers, M12 Connectors

View All

Triaxial Inclinometer, 3 Analog Outputs

View All

Bumpers

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

Axiomatic Technologies Corporation uses cookies to give you a more personalized experience on our website. If you continue to use our services, we assume that you accept such use. Learn more about cookies and how you can refuse them on our Privacy Policy page.